How Clarium is Helping Hospitals Navigate the Supply Chain Impact of Hurricane Helene

Clarium Health's AI platform helps hospitals manage supply chain disruptions caused by Hurricane Helene, ensuring continuity of care and building...

Match exceptions continue to be a growing source of pain for most hospital supply chain teams and their vendor partners alike. Increasing purchasing volumes, coupled with a rise in the complexity of purchasing and invoicing software, have contributed to an environment where it is difficult to keep up with and effectively manage match exceptions. All too often, this leads to unpleasant situations, such as credit holds, that can jeopardize the quality of patient care.

McKinsey has estimated an opportunity of $385 billion in annual savings from healthcare supply chain improvements. Supply chain expenses have jumped 16% between 2019 and 2021, increasing at a higher rate than labor or total expenses.

A recent analysis found that an average of 10% of a health system’s spend/purchase order lines end up on the exception report. Once a voucher hits the match exception report, it invariably requires a human to look at it and investigate the root cause. On the provider side, this consumes upwards of 50% of the purchasing team’s bandwidth at a leading health system, and requires similar effort from Accounts Payable and Receiving, and even involvement from clinical teams. On the vendor side, it is estimated that a single exception takes an average of 40 minutes to investigate and bring to resolution. This, combined with increasing purchasing volumes, makes this a ballooning high-value problem

Most ERP systems have their own system of creating and resolving match exceptions. Oracle’s Peoplesoft (the second leading ERP at US hospitals, after Infor) has an exception report used by the purchasing team and a Matching Workbench that is utilized by the Accounts Payable group. When an invoice is entered into PeopleSoft, the system checks a list of (matching) conditions that the invoice (or voucher in PeopleSoft terminology) needs to fulfill before it can be matched and paid, establishing a three-way match between the invoice, purchase order and receipt if applicable. Each of these conditions is related to a match rule.

While the match rules that need to be met depend on a few purchase order characteristics, if even one of the required rules is not fulfilled, the system creates a match exception, which stops the invoice from being paid.

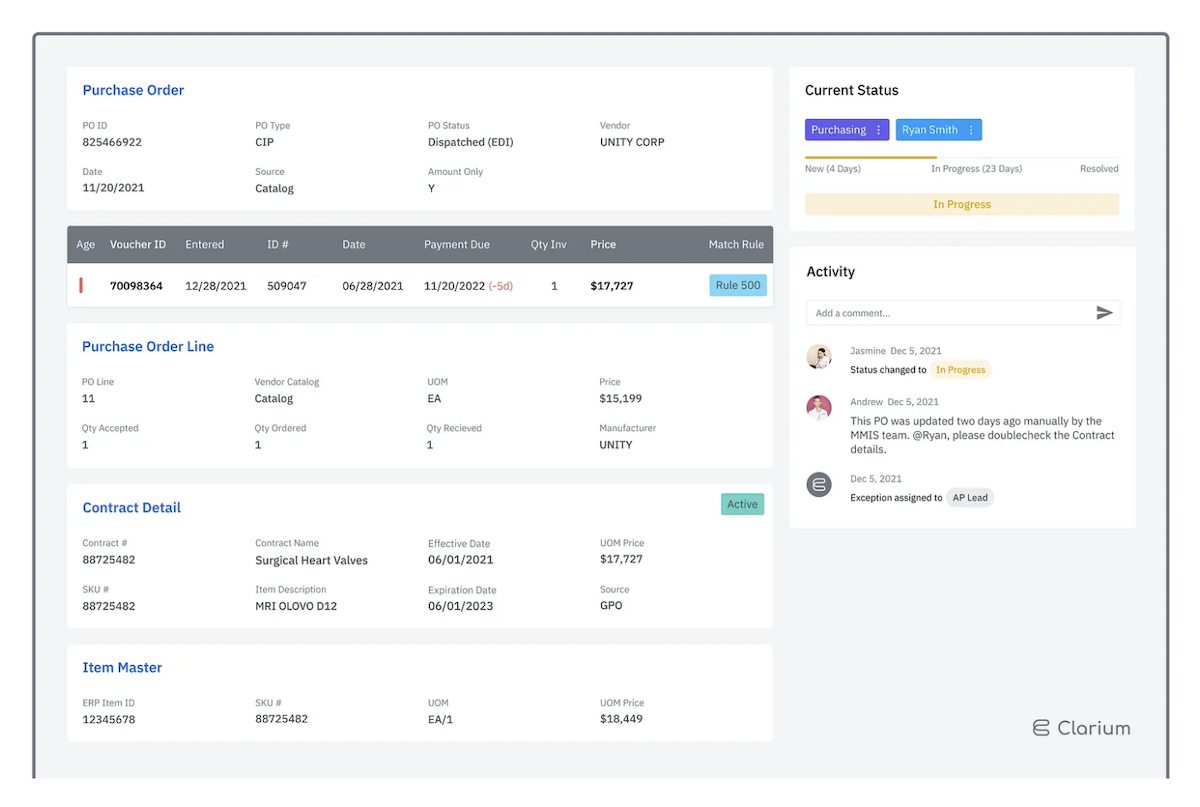

To maintain visibility of these exceptions, the purchasing team runs a recurring match exception report. This report provides a list of vouchers/invoices that failed to match and the rules they violate. Here is a sample of what that report looks like:

An average of 3,000 voucher lines translates to the report having well over 10,000 rows, making it a substantial undertaking for individual buyers to effectively manage and resolve.

During my time at a leading health system, I worked with the various groups within the supply chain to understand what each of them needed to resolve match exceptions. I designed an Excel-based report that took the stock report generated by PeopleSoft ERP and rolled it up to the PO line level, making it more digestible by the team.

This turned the 14,000+ row stock report into a 1,200-row report — with one row per purchase order line. The tool would also assign these rows to different teams based on the match rules broken. This further reduced the number of exceptions the purchasing team had to manage and thereby increased their level of efficiency. We implemented additional enhancements to create a separate view for the contracting team, which rolled exceptions up to the item level and displayed the appropriate contract information. This allowed the contracting team to fix contract-related price exceptions at the item level by fostering more efficient communication with vendors to resolve instances where prices were not honored with respect to the negotiated contracts.

This tool continues to be used by the team today, two years after it was launched. Total match exceptions dropped 20% ($2.4 million based on the hospital’s annual spend) in the 6 months following its launch, which is a considerable decrease given the increasing rate at which exceptions continue to flow in. Receiving, accounts payable, and contracting teams expressed support, given that they only get assigned issues that they own, and are provided all the information they need to resolve them.

While this report represents a big step forward from the stock report, it still has drawbacks associated with being an Excel-based report. Since the report runs daily and a new file is generated every time, the team loses access to any notes they may have made to a previous file and need to maintain those locally. Any communication about an exception needs to occur via email or offline, and it is hard to collaborate with other team members when each person has their own copy/version of the report.

Enter Exception Monitor: an integrated web application that serves as a workflow tool for healthcare supply chain teams to manage exceptions. It receives exceptions from the source ERP and maps it to other useful data such as item contracts, item master price, and price history, giving the team all the information they need to resolve an exception. They can make comments, assign exceptions to others, and track an exception from end to end.

While we are still enhancing the feature set based on user feedback, here are the highlights:

The goal of this product is to enable the supply chain team to resolve exceptions in the most efficient way possible, by minimizing the time they would spend performing non-value-add activities such as looking through their locally stored notes, copy-pasting exception information into emails, or searching for item contract information in multiple contract databases.

We want to create a seamless experience for the team, wherein they log in, know exactly what they need to do based on the priorities, and have all the information at their disposal to swiftly work toward resolution and track progress along the way. This translates to direct labor savings through increasing workforce efficiency, capital gains through prioritizing payment discounts, and reduced supply impact by minimizing and swiftly resolving credit hold situations. It is also a scalable, robust, and flexible long-term solution that increases supply-chain resilience.

Match exceptions are the symptom of a bigger problem. While Exception Monitor helps increase the outflow of exceptions (so we can live to fight another day), health systems need to also reduce the inflow. But what is the root cause of these exceptions that are flooding our purchasing teams?

Each of these areas is ripe for innovation and requires partnership across the provider-supplier spectrum to effectively resolve. We look forward to collaborating with leaders on both ends of this spectrum to build modern, robust, and resilient solutions to these problems.

Join us and learn more at clariumhealth.com.

Reuben Mathew Philip is a software engineer with a stellar record of automating and optimizing processes in the healthcare, automotive, and retail e-commerce sectors. He is passionate about leveraging computer science and big data to help hospitals dramatically reduce cost, waste, and inefficiency. At Clarium, Reuben is building intelligent automation tools that enable supply chain teams to increase productivity, lower cost, and ultimately, improve the quality of patient care. When he’s not working on modernizing the healthcare supply chain, you’ll find him running along the Charles River in Boston and singing karaoke with friends.

Clarium Health's AI platform helps hospitals manage supply chain disruptions caused by Hurricane Helene, ensuring continuity of care and building...

Discover how Clarium Health's Exception Monitor has doubled productivity and saved $500,000 annually for a leading hospital supply chain team through...

Technology partnership reduces hospital supply chain costs by $1.4M, improves efficiency, and enhances user satisfaction through AI-powered platform...